14

2025

-

05

Next-Level Heavy Machining: Technical Breakdown of Advanced Floor-Type Boring Mills

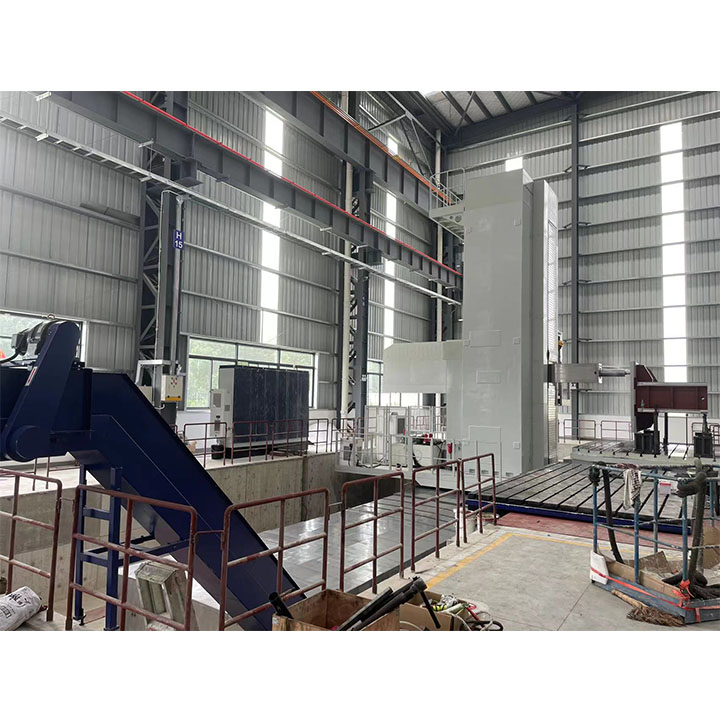

Advanced Floor-Type Boring Mills Redefine Heavy-Duty Machining This article highlights the cutting-edge technology and industrial applications of next-gen floor-type boring mills, featuring a 12m X-axis travel, 50-ton load capacity, and ISO-certified precision (0.008mm/2m)—setting new standards for mega-component machining. An AI-driven thermal compensation system with 36 infrared sensors dynamically adjusts micro-deformations, maintaining ±0.02mm accuracy during 24/7 operations. The true 5-axis configuration enables intricate contouring of turbine blades (Ra 0.4μm) and ship propeller hubs without repositioning. Ideal for energy sector applications like 5-8m wind turbine gearboxes and 10m-class hydroelectric runners, the machine also excels in aerospace machining of titanium alloy bulkheads (3mm±0.1mm wall thickness). Key innovations include a polymer-concrete base (92% vibration damping), smart tool management (30% longer insert life), and a regenerative power system recovering 25% of braking energy. These advancements drive efficiency gains and cost reductions for heavy manufacturing.

Next-Level Heavy Machining: Technical Breakdown of Advanced Floor-Type Boring Mills

——Precision Engineering for Mega-Component Manufacturing

Core Technical Specifications

| Parameter | Industry Benchmark | Advanced Floor-Type Boring Mill |

|---|---|---|

| X-Axis Travel | 6,000–8,500 mm | Up to 12,000 mm |

| Spindle Power | 30–45 kW | 55–75 kW (Peak Torque 8,000 Nm) |

| Positioning Accuracy | 0.015 mm/2m | 0.008 mm/2m (ISO 230-2 Certified) |

| Max Workpiece Weight | 15–25 metric tons | 35–50 metric tons |

| Rapid Traverse | 15–30 m/min | 50 m/min (Linear Motor Options) |

5 Game-Changing Technological Advantages

1. AI-Driven Thermal Stability

-

36-Point Thermal Compensation System

Infrared sensors embedded in columns, crossrails, and spindle housings detect micro-deformations (as small as 2μm). Machine learning algorithms adjust positioning in real-time, maintaining ±0.02mm accuracy during 24/7 operations. -

Cooling Innovation

Dual-circuit oil-air cooling reduces spindle thermal drift by 78% compared to conventional systems.

2. Multi-Axis Machining Capability

-

True 5-Axis Configuration

B-axis (±30° tilt) + C-axis (n×360° rotation) enables complex contour machining without repositioning. Ideal for:

➔ Turbine blade root profiles (Ra 0.4μm achievable)

➔ Ship propeller hubs with helical geometries -

Synchronized Motion Control

0.0001° resolution rotary tables coordinate with linear axes for true simultaneous 5-axis cutting.

3. Heavy-Duty Structural Design

-

Polymer-Concrete Hybrid Base

Damping coefficient of 92% eliminates vibration in deep boring operations (e.g., 3m-depth wind turbine main bearing housings). -

Reinforced Box-in-Box Construction

Triple-walled columns withstand 50-ton cutting forces while maintaining 0.01mm/m straightness.

4. Intelligent Process Optimization

-

Adaptive Machining Module

Automatically adjusts feed rates (up to 8,000 mm/min) and spindle loads based on real-time cutting force monitoring. -

Tool Life Prediction

Vibration sensors detect insert wear patterns, extending tool usage by 30–45%.

5. Energy-Efficient Operation

-

Regenerative Power Systems

Recovers 25% of braking energy to power auxiliary systems, reducing total energy consumption by 18–22%.

Target Applications & Industry Solutions

1. Energy Sector

-

Wind Turbine Components

-

Gearbox housings (5–8m diameter)

-

Nacelle frames (flatness ≤0.03mm/m)

-

-

Hydroelectric Systems

-

Turbine runners (6–10m diameter)

-

Stay ring profiling (true position ±0.05mm)

-

2. Aerospace & Defense

-

Rocket Engine Parts

-

Combustion chambers (Inconel 718)

-

Titanium alloy bulkheads (wall thickness 3mm±0.1mm)

-

-

Landing Gear Components

-

High-strength steel trunnions (HRC 50+)

-

3. Marine & Offshore

-

Propulsion Systems

-

10m+ diameter propeller hubs

-

Stern tube boring (straightness 0.015mm/m)

-

-

Drilling Equipment

-

Offshore platform riser flanges (ASME B16.5 compliance)

-

Operational Cost Analysis

| Cost Factor | Traditional Boring Mill | Advanced Model | Savings |

|---|---|---|---|

| Tooling Expenses | $18,000/month | $12,500/month | 30% |

| Energy Consumption | 145 kWh/hour | 108 kWh/hour | 25% |

| Setup Time | 4.5 hours/job | 1.2 hours/job | 73% |

| Scrap Rate | 2.8% | 0.6% | 79% |

Implementation Checklist

Before deploying a floor-type boring mill:

-

Facility Preparation

-

Ensure 15-ton/m² floor loading capacity

-

Maintain ambient temperature 20°C±2°C

-

-

Workholding Strategy

-

For 8m+ components: 4-point hydraulic clamping system required

-

-

Cutting Tool Selection

-

200–250mm boring bars with anti-vibration dampers

-

PCD inserts for non-ferrous alloys

-

Related news