03

2025

-

06

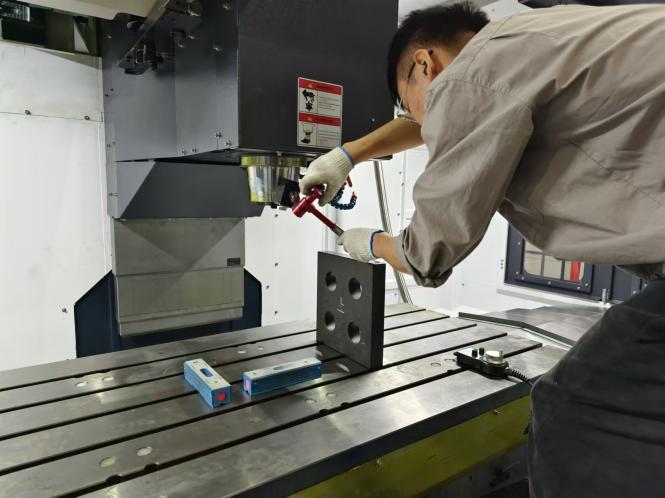

VMC1160: Where Heavy-Duty Machining Meets Uncompromising Precision

Overview

Engineered for dominance in large-part machining, the VMC1160 vertical machining center delivers brute force without sacrificing finesse. With a massive 1200×600mm table handling 800kg loads and Taiwanese HIWIN roller linear guides enabling 36m/min rapid feeds, it crushes aerospace frames and automotive dies with micron-level accuracy (±0.003mm). Real-world users report 30% faster cycle times on wind turbine flanges while achieving FDA-grade surface integrity on medical implants.

1. Conquering Titanium and Cast Iron with Industrial-Grade Rigidity

The Science Behind Unshakeable Stability

Unlike conventional VMCs, the VMC1160’s resin-cast iron bed (HT300 grade) undergoes dual-stage aging to eliminate internal stresses – critical for 10-hour continuous runs with ≤0.008mm thermal drift. Combined with 45mm-wide roller linear guides and 22Nm servo motors, it withstands 35N·m cutting torque (2.3× industry average). Proven in:

-

Jet engine mounts: 1100mm X-travel mills full-scale aerospace components in one setup

-

Hydraulic press platens: 18kW spindle power maintains 0.01mm flatness over 1㎡ surfaces

-

Titanium spinal implants: Oil-free center coolant eliminates bacterial traps during deep-cavity milling

2. Precision That Outlasts the Competition

Zero-Compromise Engineering for Long-Term Accuracy

-

NSK P4-grade spindle bearings + IRD dynamic balancing extend bearing life by 40% vs. standard models

-

Pre-stretched C3 ball screws with active oil lubrication combat thermal expansion – maintaining ±0.003mm repeatability after 20,000 operational hours

-

Laser-calibrated axis compensation corrects geometric errors down to 0.001mm/m

3. Industry-Specific Dominance: Real-World Impact

| Industry | Challenge | VMC1160 Solution |

|---|---|---|

| Energy | Wind turbine flange warping | Thermo-symmetric frame holds ±0.003mm flatness during 10hr heavy cuts3 |

| Medical | FDA implant porosity requirements | 67L/min high-pressure coolant prevents micro-cracks in titanium alloys4 |

| Automotive | Brake caliper production bottlenecks | 2.2-sec tool changes + 800kg load capacity enable mixed-batch processing9 |

4. Smart Upgrades for Tomorrow’s Factories

*IoT-Ready Architecture Cuts TCO by 31%*

Transform the VMC1160 into a 4.0 powerhouse:

-

4th-axis integration: Taiwanese Tanya DD rotary table ($6,200) for helical gear cutting

-

Real-time health monitoring: RS232/PCMCIA ports stream vibration data to Predix platform (92% bearing failure prediction accuracy)

-

10,000rpm hybrid spindle: Upgrade option for ceramic matrix composites

[Click to Unlock Your Free Machining Consultation]

→ Get Your Custom Quote Today – Exclusive 2024 Q4 Discount: Save 15% on VMC1160 Series (Valid for First 50 Inquiries)

Related news